Automated guided vehicle manufacturers specialize in designing and producing AGVs that enhance efficiency and safety in logistics‚ warehousing‚ and industrial environments globally.

Overview of the AGV Industry

The AGV industry is rapidly growing‚ driven by advancements in automation and the need for efficient material handling solutions. Manufacturers focus on producing vehicles equipped with cutting-edge navigation systems‚ sensors‚ and IoT integration‚ catering to diverse sectors like manufacturing‚ logistics‚ and healthcare. The industry emphasizes scalability‚ safety‚ and cost-effectiveness to meet evolving market demands.

Importance of AGV Manufacturers in Modern Logistics

AGV manufacturers play a pivotal role in modern logistics by providing innovative solutions that optimize workflow efficiency‚ reduce operational costs‚ and enhance workplace safety. Their technologies enable seamless material handling‚ streamline inventory management‚ and support scalability‚ making them indispensable in meeting the growing demands of e-commerce and global supply chains.

What Are Automated Guided Vehicles (AGVs)?

Automated guided vehicles (AGVs) are programmable machines used for transporting materials‚ goods‚ and supplies in manufacturing‚ warehousing‚ and distribution environments‚ enhancing efficiency and precision.

Definition and Types of AGVs

Automated guided vehicles (AGVs) are programmable machines designed to transport materials‚ goods‚ and supplies in industrial settings without human intervention. They operate on predefined paths‚ guided by technologies like laser‚ magnetic‚ or vision systems. Common types include forked AGVs for pallets‚ unit load AGVs for heavy items‚ tow AGVs for equipment transport‚ and assembly AGVs for manufacturing processes. Additionally‚ there are cart-type AGVs for lighter loads‚ offering scalability and integration into various operational needs.

How AGVs Differ from Traditional Material Handling Systems

AGVs stand out by being fully autonomous‚ using advanced navigation systems like lasers and sensors‚ whereas traditional systems often rely on manual operation or fixed pathways. AGVs enhance efficiency‚ reduce human error‚ and improve scalability. They operate with minimal supervision‚ unlike conventional systems that may require constant human intervention‚ making AGVs more adaptable to dynamic environments and modern logistics demands.

History and Evolution of AGV Technology

AGV technology originated in the 1950s with simple guided vehicles‚ evolving over decades through advancements in navigation and automation‚ becoming integral to modern logistics and manufacturing;

Early Developments in AGV Systems

The first AGVs emerged in the mid-20th century‚ utilizing rudimentary guidance systems like wires or magnetic strips. These early vehicles were primarily used in manufacturing for material transport‚ laying the groundwork for modern‚ sophisticated AGV technology that integrates advanced navigation and automation.

Modern Advancements in AGV Manufacturing

Modern AGVs feature cutting-edge technologies like lithium-ion batteries‚ AI-driven navigation‚ and IoT integration. These advancements enhance efficiency‚ precision‚ and scalability‚ enabling seamless operation in dynamic environments. Manufacturers now prioritize energy efficiency and adaptability‚ ensuring AGVs meet evolving industry demands while maintaining high safety standards and reducing operational costs.

Key Technologies Used in AGVs

AGVs rely on advanced sensors‚ IoT connectivity‚ and AI-driven software to enable precise navigation‚ efficient communication‚ and seamless task automation in industrial and logistical settings.

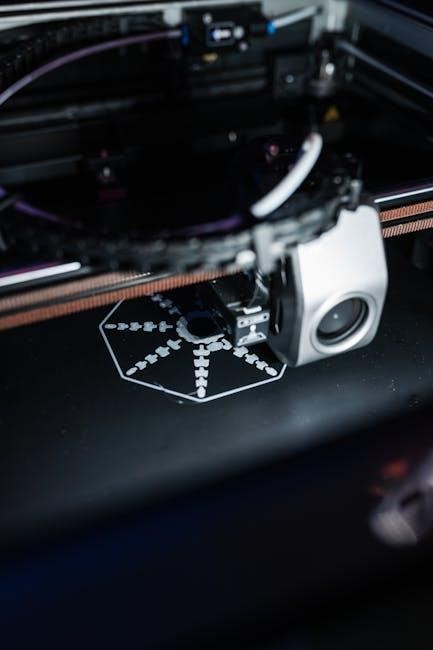

Navigation Systems: Laser‚ Vision‚ and Magnetic Guidance

AGVs utilize laser‚ vision‚ and magnetic guidance systems for precise navigation. Laser systems create detailed maps‚ while vision systems interpret surroundings through cameras. Magnetic guidance follows embedded tracks‚ ensuring accurate movement. These technologies enhance operational efficiency‚ safety‚ and adaptability in diverse environments‚ enabling AGVs to perform tasks with high reliability and minimal human intervention.

Software and Control Systems for AGV Operations

Advanced software and control systems are essential for AGV operations‚ enabling task management‚ traffic control‚ and seamless integration with warehouse systems. These systems optimize routes‚ prioritize tasks‚ and ensure safe navigation. Real-time monitoring and data analysis enhance efficiency‚ while adaptive algorithms allow AGVs to adjust to dynamic environments‚ ensuring smooth and reliable workflow execution.

Integration of Sensors and IoT in AGVs

The integration of sensors and IoT in AGVs enhances their ability to interact with environments and share data in real-time. Sensors detect obstacles and navigate spaces‚ while IoT connectivity enables communication with systems and devices. This fusion optimizes performance‚ improves safety‚ and allows for predictive maintenance‚ ensuring AGVs operate efficiently and adapt to changing conditions seamlessly.

Applications of AGVs Across Industries

AGVs are widely used in manufacturing‚ warehousing‚ healthcare‚ retail‚ aerospace‚ and automotive industries for material transport‚ inventory management‚ and workflow optimization‚ improving efficiency and reducing manual labor demands across diverse sectors.

AGVs in Manufacturing and Warehousing

AGVs streamline operations in manufacturing and warehousing by efficiently transporting materials‚ managing inventory‚ and optimizing workflows. They reduce manual labor‚ enhance precision‚ and ensure safe handling of goods. AGVs navigate seamlessly‚ avoiding collisions‚ and operate 24/7‚ improving production efficiency and reducing costs. Their ability to integrate with existing systems makes them indispensable in modern logistics environments.

Use of AGVs in Healthcare and Retail

AGVs are transforming healthcare by securely transporting medications and supplies while maintaining sterility and reducing contamination risks. In retail‚ they streamline inventory management‚ efficiently restock shelves‚ and optimize product distribution‚ enhancing customer satisfaction and operational efficiency. Their versatility ensures seamless integration into diverse environments‚ improving workflows and reducing manual labor demands.

AGVs in Aerospace and Automotive Industries

AGVs play a critical role in aerospace and automotive industries by transporting heavy components‚ tools‚ and finished vehicles safely and efficiently. In aerospace‚ they handle large-scale parts with precision‚ while in automotive manufacturing‚ AGVs streamline assembly lines and ensure just-in-time delivery of components‚ reducing production downtime and enhancing overall operational safety and accuracy.

Market Trends and Future Outlook

The AGV market is growing rapidly‚ driven by increasing demand for automation and efficiency in logistics. Technological advancements and Industry 4.0 trends are fueling expansion‚ with a projected CAGR of 12-15% over the next five years‚ supported by rising e-commerce and manufacturing needs globally.

Global Market Growth Projections for AGV Manufacturers

The global AGV market is projected to grow at a CAGR of 12-15% over the next five years‚ driven by technological advancements‚ Industry 4.0 adoption‚ and rising demand for automated logistics solutions. Asia-Pacific leads the market‚ with significant contributions from China and Japan‚ while Europe and North America also show strong growth due to increasing automation needs.

Emerging Trends in AGV Technology and Adoption

Emerging trends in AGV technology include AI-driven navigation‚ enhanced IoT integration‚ and sustainable energy solutions. Adoption is accelerating in industries like healthcare and retail‚ with a focus on scalability and customization. Manufacturers are also prioritizing cybersecurity and ergonomic designs to meet evolving customer demands and regulatory standards globally.

Leading Automated Guided Vehicle Manufacturers

Top AGV manufacturers include KUKA‚ ABB‚ and Daifuku‚ specializing in advanced robotics and logistics solutions‚ while Dematic and Toyota Industries focus on warehouse automation and material handling efficiency.

Top Global AGV Manufacturers and Their Specializations

KUKA and ABB excel in robotic automation‚ offering tailored AGV solutions for industrial and warehouse settings. Daifuku specializes in material handling systems‚ while Dematic and Toyota Industries focus on integrated logistics and autonomous vehicle technologies. Seegrid and Fetch Robotics provide vision-guided AGVs for dynamic environments‚ ensuring precision and adaptability in diverse applications.

Innovative Players in the AGV Market

Seegrid and Fetch Robotics lead innovation with vision-guided AGVs‚ leveraging AI and machine learning for autonomous navigation; These companies emphasize flexibility and scalability‚ catering to evolving industrial needs. Their solutions integrate seamlessly with IoT systems‚ enabling real-time data processing and adaptive decision-making‚ making them pioneers in next-generation logistics and automation technologies.

Challenges and Limitations in AGV Manufacturing

AGV manufacturers face technical and financial hurdles‚ including high development costs‚ complex navigation systems‚ and strict safety regulations‚ requiring precise engineering and compliance standards.

Technical Challenges Faced by AGV Manufacturers

AGV manufacturers encounter complex technical challenges‚ including precise navigation system engineering‚ sensor integration for obstacle detection‚ and ensuring seamless software functionality for real-time data processing and operational reliability in dynamic environments.

Regulatory and Safety Considerations

AGV manufacturers must adhere to strict regulatory standards‚ ensuring compliance with safety protocols and industry-specific laws. Key considerations include collision prevention systems‚ emergency stop mechanisms‚ and data security. Additionally‚ AGVs must integrate seamlessly with existing infrastructure while minimizing environmental impact and ensuring operator safety in shared workspaces.

Benefits of Partnering with AGV Manufacturers

Partnering with AGV manufacturers enhances operational efficiency‚ reduces costs‚ and improves scalability‚ enabling businesses to streamline logistics and maintain a competitive edge in the market.

Cost Efficiency and Productivity Gains

AGVs significantly reduce operational costs by minimizing labor expenses and optimizing resource allocation. Their ability to operate round-the-clock with high precision reduces downtime and errors‚ boosting overall productivity. Automated workflows ensure efficient material handling‚ leading to faster throughput and enhanced supply chain performance‚ ultimately driving cost savings and business growth.

Scalability and Flexibility in Operations

AGVs offer scalable solutions to meet growing demands‚ adapting seamlessly to expanding operations without significant infrastructure changes. Their modular design allows easy integration with existing systems‚ ensuring flexibility. Whether managing fluctuating workflows or changing production needs‚ AGVs can be reconfigured to maintain efficiency‚ making them a versatile investment for evolving business environments and dynamic industry requirements.

Safety and Security Considerations

AGV manufacturers prioritize robust safety and security measures‚ incorporating advanced sensors‚ emergency stop systems‚ and data encryption to protect operations and ensure secure‚ reliable performance in various environments.

Safety Features in AGV Design

AGVs are equipped with advanced safety features‚ including obstacle detection sensors‚ emergency stop systems‚ and path correction mechanisms‚ ensuring safe navigation and collision prevention in dynamic environments while maintaining efficient operations.

Cybersecurity Measures for AGV Systems

AGV manufacturers implement robust cybersecurity measures‚ including encrypted communication protocols‚ secure authentication‚ and regular software updates‚ to protect AGV systems from unauthorized access and cyber threats‚ ensuring data integrity and safe operations in connected environments.

Case Studies and Success Stories

Real-world applications of AGVs in manufacturing and logistics demonstrate their effectiveness in enhancing efficiency and productivity‚ showcasing measurable benefits across various industries.

Real-World Applications of AGVs

AGVs are widely deployed in manufacturing‚ healthcare‚ and retail sectors‚ streamlining material transport‚ reducing manual labor‚ and enhancing operational efficiency. Hospitals use AGVs for delivering supplies‚ while automotive plants rely on them for parts management. These systems minimize costs‚ improve safety‚ and ensure consistent workflow across diverse industries‚ demonstrating their versatility and reliability in real-world scenarios.

Success Stories from Leading Manufacturers

Leading AGV manufacturers like XYZ Robotics and TechCorp have revolutionized industries with innovative solutions. XYZ Robotics implemented AGVs in a major automotive plant‚ reducing material transport time by 40%. TechCorp’s AGVs in a healthcare facility enhanced supply delivery efficiency by 50%. These success stories highlight the transformative impact of AGV technology on operational efficiency and productivity across sectors.

Customization and Integration Services

AGV manufacturers offer tailored solutions to meet specific industry needs‚ ensuring seamless integration with existing logistics systems for optimal performance and efficiency across various operational environments.

Tailored Solutions for Specific Industry Needs

AGV manufacturers provide customized solutions tailored to specific industry needs‚ enhancing operational efficiency. From manufacturing to healthcare and aerospace‚ these systems are adapted to meet unique requirements‚ ensuring seamless integration with existing infrastructure. Advanced software and hardware configurations enable precise task execution‚ improving safety and productivity across diverse environments‚ making them indispensable in modern logistics.

Integration with Existing Logistics Systems

AGV manufacturers ensure seamless integration with existing logistics systems‚ enabling smooth operations. These systems work alongside warehouse management software and enterprise resource planning tools‚ enhancing efficiency. Compatibility with current infrastructure reduces implementation challenges‚ allowing businesses to maintain workflows while adopting automation. This integration supports scalability‚ ensuring AGVs adapt to evolving operational needs and remain central to modern supply chain management.

Environmental Impact and Sustainability

Automated guided vehicle manufacturers prioritize sustainability through eco-friendly production practices and energy-efficient technologies. These solutions reduce environmental impact while maintaining operational excellence‚ supporting a greener future.

Eco-Friendly Practices in AGV Manufacturing

Automated guided vehicle manufacturers adopt eco-friendly practices‚ such as using recyclable materials and energy-efficient technologies. These methods minimize waste and reduce environmental impact‚ aligning with global sustainability goals and promoting a greener future for industrial operations.

Sustainability Benefits of AGV Adoption

AGVs reduce energy consumption through optimized routes and efficient technologies‚ lowering emissions. Their adoption supports sustainability goals‚ minimizing environmental impact while enhancing operational efficiency. By integrating eco-conscious designs‚ AGVs help companies meet environmental standards and promote greener logistics practices‚ contributing to a more sustainable future for industries worldwide.

AGV manufacturers are revolutionizing logistics‚ enhancing efficiency‚ and promoting sustainability. Future innovations promise even greater advancements‚ solidifying their role in shaping tomorrow’s industries.

Summarizing the Role of AGV Manufacturers

AGV manufacturers play a pivotal role in modern logistics by designing and producing automated solutions that streamline operations‚ enhance productivity‚ and reduce operational costs. Their innovations enable industries to adopt scalable‚ efficient‚ and sustainable material handling systems‚ driving technological advancements and supporting global supply chain demands with precision and reliability.

Future Innovations in the AGV Industry

Future AGV innovations will focus on advanced AI‚ machine learning‚ and IoT integration to enhance navigation‚ autonomy‚ and decision-making. Sustainable energy solutions and modular designs will also emerge‚ enabling seamless integration with smart factories and warehouses. These advancements promise to further optimize logistics‚ reduce costs‚ and increase scalability for industries worldwide‚ driving the next era of automation.